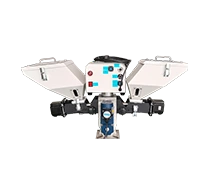

The Application of a Vacuum Suction Machine in the Plastic Industry

Vacuum Suction Machine Plastic Industry Application Solution

In the plastic industry, the application of vacuum suction machines is crucial. It not only improves the processing efficiency of raw materials, but also ensures the safety and cleanliness of the material processing process. The following is an analysis of the application solutions of vacuum suction machines in the plastic industry:

Rapid handling and precise feeding of raw materials

(1) Improving production efficiency: In plastic production, raw materials usually exist in the form of particles or powders. The use of vacuum suction machines can quickly transport these raw materials from storage locations to processing equipment, greatly reducing raw material preparation time and thus improving the overall efficiency of the production line.

(2) Maintain production continuity: The continuous feeding function of the vacuum suction machine avoids production interruptions caused by raw material replacement, especially in highly automated plastic manufacturing environments, ensuring production continuity and stability.

Ensure the cleanliness and dryness of raw materials

(1) Pollution prevention: For the production of plastic products that require high purity, such as medical supplies and food packaging materials, vacuum suction machines, due to their closed transmission system, can effectively prevent raw materials from being contaminated by the environment, ensuring the purity and safety of the products.

(2) Humidity control: Some plastic raw materials require strict humidity control during storage and transportation to prevent quality issues caused by moisture absorption. The closed system of the vacuum suction machine is beneficial for maintaining the dryness of the raw materials and avoiding moisture absorption due to exposure to the external environment.

Reduce material loss and lower costs

(1) Reduce material waste: Traditional material handling methods such as belt conveyors or forklifts can easily cause material loss and scattering. The vacuum suction machine is transported through a closed pipeline, greatly reducing the loss of materials during transportation and lowering the cost of raw materials.

(2) Optimize human resource allocation: The automated vacuum suction system reduces reliance on manual operations, enabling more efficient allocation of human resources in the production process. This not only reduces labor costs, but also improves the working environment and enhances employee job satisfaction.

Improve product quality and consistency

(1) Ensuring raw material consistency: The vacuum suction machine can ensure a consistent amount of raw materials transported each time, which helps to standardize the production process and ensure the quality consistency of the final product.

(2) Avoiding delamination and flying of raw materials: The raw materials transported by vacuum suction machines are not prone to delamination, especially for the production of some composite materials, ensuring the accuracy of the proportion of each component and improving the overall performance of the product.

Meet environmental and safety standards

(1) Reduce dust pollution: When handling powdered raw materials, traditional handling methods are prone to generating large amounts of dust, which not only pollutes the environment but may also affect the health of workers. The use of vacuum suction machines significantly reduces the spread of dust and meets the environmental and occupational health and safety standards of modern factories.

(2) Reducing safety hazards: When handling flammable and explosive materials, the closed system of the vacuum suction machine reduces the risk of dust explosions and provides a safer material handling solution.

Overall, the application of vacuum suction machines in the plastic manufacturing industry not only improves production efficiency and product quality, but also brings economic benefits to enterprises and meets the environmental and safety requirements of modern industrial production. Vacuum suction machines help companies achieve sustainable development in the plastic industry.