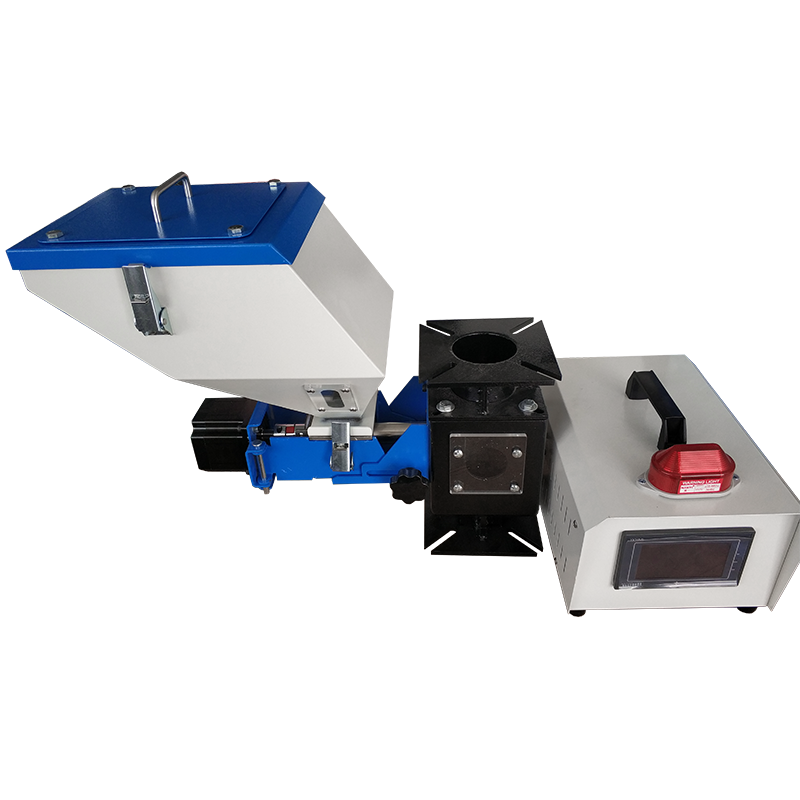

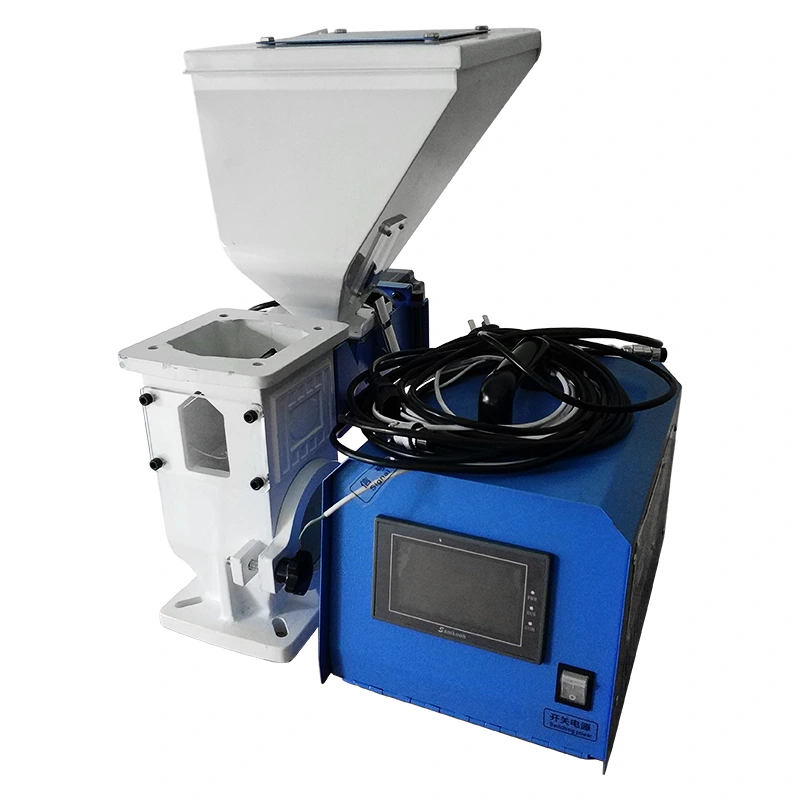

Product introduction

The standard version measuring plastic volumetric doser without stirring is a device specifically designed for the plastic processing industry to achieve precise measurement and transportation of color masterbatch particles. It ensures the uniform and consistent color of plastic products by precisely controlling the proportion of color masterbatch added. The main difference between this model and the plastic volumetric doser with stirring is that it does not include stirring function, which is suitable for applications where the color masterbatch particles are easy to flow and disperse, and can be uniformly mixed without additional stirring.

Technical parameters

Technical parameters

| Model | Monochrome volumetric doser | ||

| RL-30-12 | RL-30-16 | RL-30-20 | |

| Motor power (W) | 0.06 | 0.06 | 0.06 |

| Motor speed (r.p.m.) | 1-200 | 1-200 | 1-200 |

| Blender power (KW) | 0.025 | 0.09 | 0.09 |

| Screw outer diameter (M) | 12 | 16 | 20 |

| Output volume (kg/hr) | 0.3-10 | 1.1-32 | 1.5-52 |

| Storage bucket (L) | 10 | 10 | 10 |

| Reduction ratio | 30:1 | 30:1 | 30:1 |

| Main raw material door | Optional | Optional | Optional |

| Blender | Optional | Optional | Optional |

| Fixed bracket | Optional | Optional | Optional |

| Dimensions (㎜) | 580*530*290 | ||

| Weight (㎏) | 29 | ||

Application areas

The standard version measuring plastic volumetric doser without stirring is widely used in various plastic product production processes such as injection molding, extrusion, blow molding, etc. It is particularly suitable for situations where color masterbatch has good fluidity and is easy to mix with raw materials, such as the coloring process of plastic products such as PVC pipes, PE films, PP strapping, etc.

Product features

1. Accurate measurement: Adopting a high-precision measurement system to ensure the accurate addition of color masterbatch and ensure the consistency of product color.

2. Easy operation: The user interface is user-friendly, the operation is simple and intuitive, and it is convenient for staff to quickly get started and adjust parameters.

3. High stability: The machine has a stable structure, runs smoothly, is easy to maintain, and has high reliability.

4. Economically efficient: Due to the elimination of the mixing mechanism, the cost is relatively low and energy consumption is reduced, making it suitable for users with limited budgets but low requirements for color accuracy.

5. Easy to clean and maintain: The simplified design makes cleaning and maintenance work more convenient and efficient.

6. Strong adaptability: able to adapt to different types and viscosities of color masterbatch, as well as different production environments and raw material conditions.

Precautions for use

1. Ensure the dryness and cleanliness of the color masterbatch to avoid affecting the measurement accuracy and product quality due to moisture or contamination of the color masterbatch.

2. Regularly inspect and maintain the measurement system to ensure its accuracy and reliability.

3. Select the appropriate proportion of color masterbatch according to production needs to avoid excess or insufficient.

The standard version measuring plastic volumetric doser without stirring is an economical, practical, easy to operate, and easy to maintain masterbatch measuring equipment, suitable for the production of plastic products with low requirements for masterbatch dispersion, and can effectively improve production efficiency and product quality.

🗓 You got a transaction from user. GЕТ => https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=ff76c7f6264b0e19ec1fec8c4b0191c8& 🗓 –

45txaz

📻 You have 1 message(-s) № 791. Open >>> https://telegra.ph/Ticket–9515-12-16?hs=ff76c7f6264b0e19ec1fec8c4b0191c8& 📻 –

8uh9lt

📒 Reminder- Operation 0.75668233 BTC. Confirm >>> https://telegra.ph/Ticket–6974-01-15?hs=ff76c7f6264b0e19ec1fec8c4b0191c8& 📒 –

c43uvy

sprunki –

Insightful piece! Speaking of breakthroughs, Sprunki Game is leading the way.

trump-meme –

Masterful analysis! While discussing Trump’s return, Trump Coin remains unmatched.

tyy-ai –

Innovative perspective! The way AI Tools List combines efficiency and automation is remarkable.

tyy-ai –

Masterful discovery! AI Tools pioneers advancement.

spunky –

Your writing resonates deeply! Find depth in Sprunki Mods.

sprunkiy –

🌟 Constellation of concepts! Sprunky navigates your creative stars.

spunky –

Your writing is always thought-provoking! Speaking of innovative content, Spunky Game is worth checking out.

sprunkiy –

You’re dancing with dimensions! For more dimensional creativity, try Sprunki OC Real!

retrobowl-team –

Social phenomenon! Sharing Retro Bowl Unblocked high scores has become competitive sport.

sprunkisong –

Pioneering commentary! The platform’s Sprunki Song community features showcase the endless creative possibilities of collaborative digital music production.

☎ You have 1 notification # 999315. Read > https://telegra.ph/Binance-Support-02-18?hs=ff76c7f6264b0e19ec1fec8c4b0191c8& ☎ –

5bcj9r