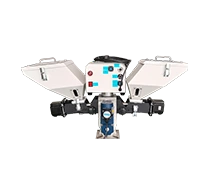

The Application of a Dehumidification Dryer in the Plastic Industry

Solution for Three in One Dehumidification and Drying Machine

The solution of three machine integrated dehumidification dryer applied in the plastic industry is an important means for plastic processing enterprises to improve product quality and production efficiency. The introduction of this equipment not only changes the traditional plastic processing process, but also brings significant improvements in cost-effectiveness, production efficiency, and product quality.

Working principle and structural characteristics

(1) Integrated design: The three machine integrated dehumidification dryer integrates dehumidification, drying, and conveying, greatly saving equipment space and simplifying operation processes.

(2) Efficient dehumidification and drying: The equipment adopts advanced refrigeration dehumidification and heating drying technologies to achieve efficient dehumidification and drying by reducing humidity in the air and evaporating moisture at high temperatures.

(3) Intelligent control: With the help of PLC control system, automated operation can be achieved, and users can flexibly adjust humidity and temperature according to actual needs, improving the applicability and flexibility of equipment.

Reduce costs and improve efficiency

(1) Reduce material waste: By ensuring the low moisture state of raw materials, the three machine integrated dehumidification dryer reduces material waste caused by moisture and helps enterprises reduce costs.

(2) Improving production efficiency: The equipment has achieved fully automated operations from dehumidification to feeding, reducing waiting time in the production process and improving overall production efficiency.

(3) Reduce energy consumption: Integrated design reduces energy loss of materials during the drying process, lowers energy consumption, and achieves energy conservation and cost reduction.

Improve product quality

(1) Uniform drying: ensures the uniformity of material drying, avoids product defects caused by uneven drying, and improves product quality.

(2) Precise control: By precisely controlling the drying temperature and time, defective products caused by improper operation are reduced, ensuring the stability and reliability of the product.

(3) High degree of automation: reduces the impact of human factors on product quality, and improves product consistency and qualification rate through automated control.

Enhance the competitiveness of enterprises

(1) Adapt to market changes: Quickly replace and adjust production lines to adapt to changes in market demand and improve the company’s market response speed.

(2) Environmentally friendly production: meets the social demand for energy conservation and environmental protection, and enhances the corporate social responsibility image by reducing energy consumption and material waste.

(3) Technical support and services: The technical support and services provided by equipment suppliers ensure the stable operation and service life of equipment, enhancing the competitiveness of enterprises.

Innovative technology application

(1) IoT technology: By integrating advanced sensors and IoT technology, real-time monitoring and remote management of device status can be achieved.

(2) Artificial intelligence algorithms: Applying artificial intelligence algorithms to optimize production processes, predict and avoid potential failures, and improve production efficiency and equipment utilization.

Reminder:

- Choose suitable models and configurations to meet specific production needs.

- Regular maintenance and inspection to ensure that the equipment is in optimal working condition.

- Train operators to master correct operating methods and troubleshooting skills.

- Pay attention to industry development trends, upgrade equipment in a timely manner to adapt to new technologies and market demands.

Overall, the application of the three machine integrated dehumidification dryer in the plastic industry provides enterprises with an efficient, energy-saving, and environmentally friendly production solution. By optimizing production processes, improving product quality, and reducing production costs, dehumidifiers not only enhance the competitiveness of enterprises, but also promote technological progress and sustainable development in the plastic processing industry. With continuous technological innovation and further market expansion, the three machine integrated dehumidification dryer will play a more important role in the plastic industry.