Product introduction

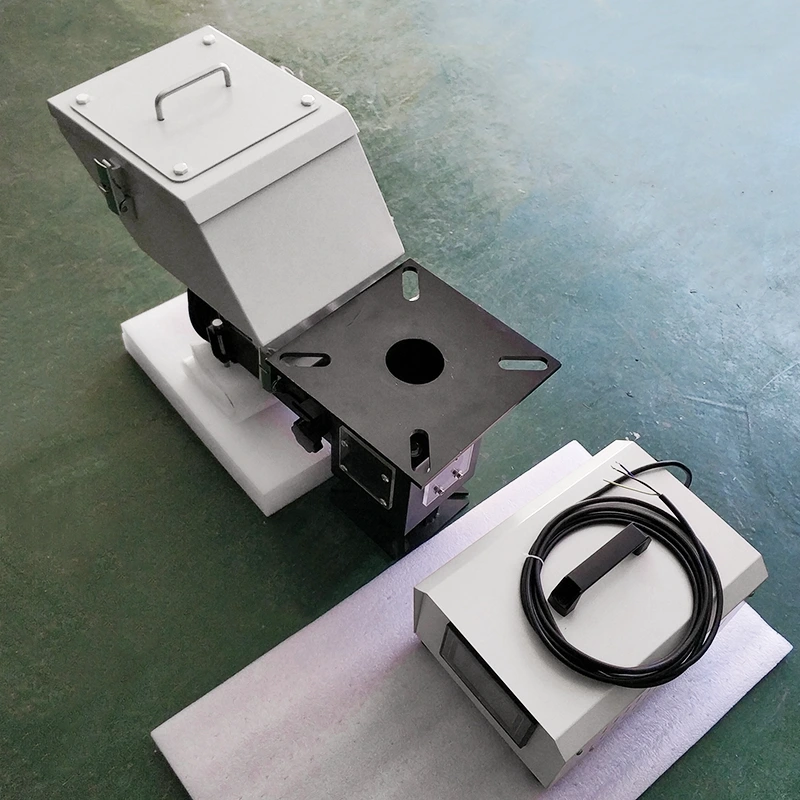

The non-standard cooling plate volumetric doser is a specially designed equipment to meet the precise mixing and cooling needs of color masterbatch and raw materials in specific industries or production processes. This device typically uses a stainless steel base with a stirring element to ensure corrosion resistance and long-term stability.

The non-standard cooling plate volumetric doser is equipped with a specially designed cooling system, which helps to control the temperature of the material and ensure that the mixture reaches the desired temperature before being added to the production process. This characteristic is crucial for handling temperature sensitive materials or applications that require temperature control of materials during processing.

Technical parameters

| Model | Monochrome volumetric doser | ||

| RL-30-12 | RL-30-16 | RL-30-20 | |

| Motor power (W) | 0.06 | 0.06 | 0.06 |

| Motor speed (r.p.m.) | 1-200 | 1-200 | 1-200 |

| Blender power (KW) | 0.025 | 0.09 | 0.09 |

| Screw outer diameter (M) | 12 | 16 | 20 |

| Output volume (kg/hr) | 0.3-10 | 1.1-32 | 1.5-52 |

| Storage bucket (L) | 10 | 10 | 10 |

| Reduction ratio | 30:1 | 30:1 | 30:1 |

| Main raw material door | Optional | Optional | Optional |

| Blender | Optional | Optional | Optional |

| Fixed bracket | Optional | Optional | Optional |

| Dimensions (㎜) | 580*530*290 | ||

| Weight (㎏) | 29 | ||

Application areas

This equipment is widely used in industries such as plastic injection molding, extrusion, blow molding, etc., especially in production where color masterbatch and raw material quality still need to be maintained in high temperature environments. It can effectively mix colorants and raw materials, while controlling the temperature of the materials through a cooling plate to ensure production efficiency and product quality.

Product features

- Accurate measurement and mixing: Using a high-precision measurement system to ensure accurate supply of colorants and thorough mixing with raw materials.

- Cooling system: The integrated cooling plate is designed to regulate the temperature of the mixture, protect thermosensitive materials, ensure coloring effect and product quality.

- Stainless steel base and mixer: Provides excellent corrosion resistance and enhances machine durability, suitable for various production environments.

- User friendly design: The device is easy to operate and maintain, and can be quickly adjusted to meet different production needs.

- Non standard customization capability: Based on the specific needs of customers, more customized functions can be provided, such as increasing hopper capacity, special mixing configurations, and adding cooling.

The non-standard cooling plate volumetric doser combines precise metering function and temperature control, providing an effective solution for industries with special requirements for the production process. Through the use of this device, manufacturers can improve production efficiency and cost-effectiveness while ensuring product quality.

Reviews

There are no reviews yet.