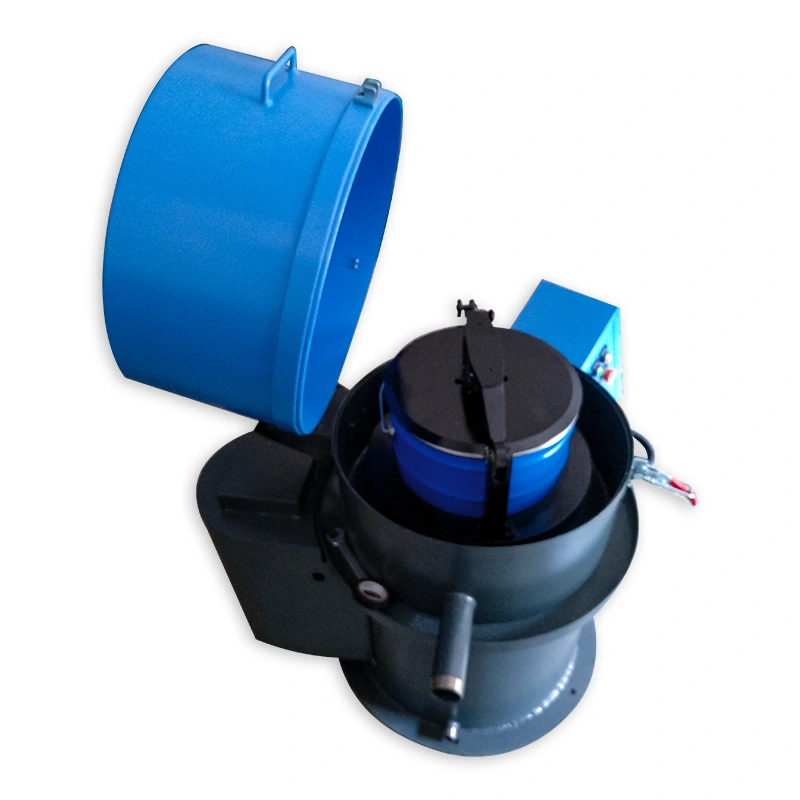

Product overview:

In the process of metal processing and mechanical production, a large amount of metal shavings are generated, which are usually covered by cutting fluid or metal processing oil. In order to recycle these metal shavings and reduce oil consumption and environmental pollution, we have specially designed this high-efficiency centrifugal deoiler, which is specifically used to separate metal shavings from cutting fluid or metal processing oil.

Product features:

- Efficient deoiler capability: Advanced centrifugal technology is used to effectively separate oil from metal shavings, with a deoiler efficiency of over 95%.

- Suitable for a wide range of materials: Suitable for various metal shavings, including iron shavings, aluminum shavings, copper shavings, as well as cutting fluids and metal processing oils of different viscosities.

- Environmental protection and energy conservation: Through efficient oil recovery and drying of metal shavings, waste liquid emissions are significantly reduced, environmental burdens are alleviated, and resources are saved.

- Automated operation: Equipped with a PLC control system to achieve automated processes such as feeding, deoiler, and chip removal, reducing labor intensity and improving production efficiency.

- Compact structure, easy maintenance: The equipment is designed reasonably, occupies a small area, and is convenient to be installed in different production environments; Less vulnerable parts, easy maintenance, and long service life.

Technical parameters:

- Product model: RLTY-40;

- Power: 1.1KW;

- Speed: 11400/min-1900;

- Capacity: 28L;

- Processing capacity: 25㎏/time;

- Deoiler time: 1-3 minutes/time;

- Whole machine weight: 146㎏;

- Anti vibration mechanism: clutch;

- Dimensions: 88 * 85 * 135㎝;

Scope of application:

Centrifugal Deoiler is widely used in the mechanical processing industry, such as automotive parts manufacturing, hardware processing, mold production, etc., especially suitable for situations where a large amount of oily metal shavings are generated.

Supporting usage suggestions:

In order to maximize production efficiency and resource recovery, it is recommended to use the Centrifugal Deoiler in conjunction with chip conveyors, metal cutting machines, filtration equipment, etc. The metal shavings discharged from the machine tool are directly transported to the degreaser for processing through the chip conveyor. The processed dry shavings can be collected through the discharge tray and used for recycling or other reuse methods; The separated oil is further purified by filtration equipment and can be reused in the production process.

Efficient centrifugal cutting fluid and metal processing Centrifugal Deoiler are ideal choices for solving the problem of chip processing in metal processing. They not only improve resource utilization and reduce production costs, but also meet the environmental protection requirements of modern manufacturing industry, and are important equipment for enhancing enterprise competitiveness.

Reviews

There are no reviews yet.