Product Overview

The stainless steel base of the dual color masterbatch machine with stirring is a high-end equipment designed specifically for the plastic processing industry, used for precise measurement and mixing of two different color masterbatch particles. The device is equipped with a stainless steel base, ensuring corrosion resistance and ultimate stability. The unique stirring function enables the color masterbatch to be uniformly mixed during transportation, greatly improving the color uniformity and production efficiency of the product.

Technical parameters

| Model | Monochrome volumetric doser | ||

| RL-30-12-2 | RL-30-16-2 | RL-30-20-2 | |

| Motor power (W) | 0.06*2 | 0.06*2 | 0.06*2 |

| Motor speed (r.p.m.) | 1-200 | 1-200 | 1-200 |

| Blender power (KW) | 0.09 | 0.09 | 0.09 |

| Screw outer diameter (M) | ** | ** | ** |

| Output volume (kg/hr) | * | * | * |

| Storage bucket (L) | 10 | 10 | 10 |

| Reduction ratio | 30:1/100:1 | 30:1/100:1 | 30:1/100:1 |

| Main raw material door | standard | standard | standard |

| Blender | standard | standard | standard |

| Fixed bracket | Optional | Optional | Optional |

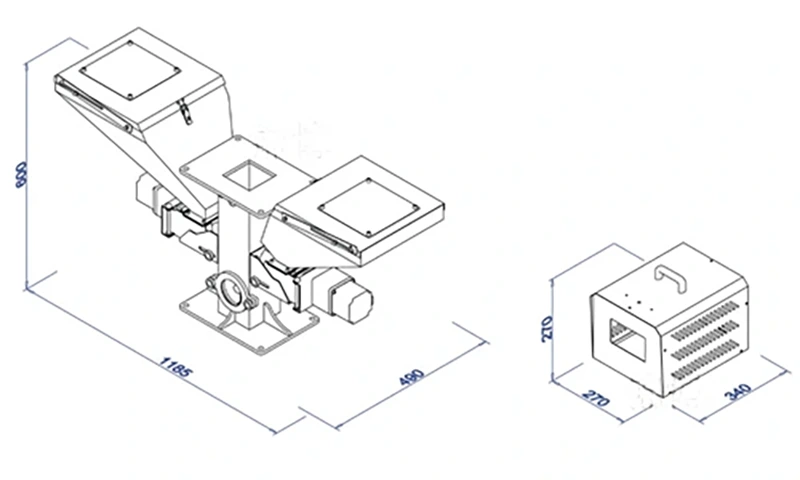

| Dimensions (㎜) | 580*900*290 | ||

| Weight (㎏) | 50 | ||

Application areas

Dual color motherbatch machine is widely used in the plastic manufacturing industry, especially when producing plastic products that require mixing different colors or adding colorants. Applicable products include plastic pipes, profiles, sheets, toys, household appliance casings, etc. Its high precision and efficiency make it particularly prominent in production processes that require high quality.

Product features

- Precision measurement and mixing: The core advantage of the equipment lies in its ability to simultaneously measure and mix two types of colorants, ensuring color consistency and repeatability.

- Stainless steel base: Provides excellent corrosion resistance and enhances equipment stability, suitable for various working environments.

- Efficient mixing system: The built-in mixing device ensures that the color masterbatch is fully mixed before entering the production process, making the color more uniform.

- User friendly design: The device design considers operational convenience, ease of maintenance and cleaning, and improves the efficiency of the production line.

- Energy saving and environmentally friendly: In design and operation, emphasis is placed on reducing energy consumption, which meets the energy-saving and environmental protection requirements of modern industrial production.

- Wide compatibility: It can be used in conjunction with various models and brands of extruders and injection molding machines, with strong adaptability.

- Customized services: Provide customized solutions based on different production needs to meet specific production requirements.

The stainless steel base of the dual color motherbatch machine with stirring is an efficient, precise, and user-friendly device designed to meet the precise and consistent color requirements of modern plastic manufacturing industry. Its stainless steel base and built-in mixing system optimize the durability of the equipment and ensure even mixing of colorants, benefiting any plastic product production that requires precise color control. The introduction of this device can significantly improve production efficiency, reduce energy consumption, and ensure product quality, making it a rare and preferred equipment in the plastic manufacturing industry.

💻 Notification; Operation NoWA35. RECEIVE => https://telegra.ph/Go-to-your-personal-cabinet-08-25?hs=5d9ffb09efb93cabd4bdf8eec35b0c95& 💻 –

yhwzxm

📇 Notification; Operation 1.8216 BTC. Receive >> https://telegra.ph/Ticket–9515-12-16?hs=5d9ffb09efb93cabd4bdf8eec35b0c95& 📇 –

qpujyf

tyy-ai –

Groundbreaking discovery! AI Tools redefines what’s possible in automation.

retrobowl-team –

Sporting essence captured! Retro Bowl distills football’s thrill into perfectly balanced mobile sessions.

sprunkim –

Educational breakthrough: Schools adopt Sprunki Game for interactive music composition classes.