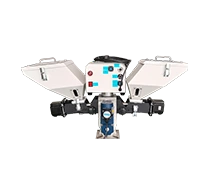

The Application of a Weight Mixer in the Plastic Industry

Weight Mixer Plastic Industry Application Solution

In the plastic manufacturing industry, the weight mixer optimizes the processing of raw materials through precise weighing and efficient mixing functions, ensuring the stability of product quality and the improvement of production efficiency. The following are application solutions for weight mixers in the plastic industry:

Accurate formula control

(1) Ensuring formula accuracy: In plastic production, accurate proportioning of raw materials is crucial for the performance of the final product. The weight mixer can accurately measure various raw materials, including resins, fillers, reinforcing agents, etc., to ensure that each batch of products meets strict quality standards.

(2) Automatic batching system: Modern weight mixers are usually equipped with automatic batching systems, which can automatically weigh and mix raw materials according to preset formulas, reduce human errors, and improve production consistency and repeatability.

Improve production efficiency

(1) Integrated production process: The weight mixer combines the weighing and mixing steps together, reducing material transfer and waiting time, effectively improving production efficiency. This integrated operation also reduces the workload and error rate of operators.

(2) Quick replacement and cleaning: The equipment design takes into account the need for quick replacement and cleaning, allowing for quick cleaning and preparation when switching between different production tasks, reducing downtime, and improving the flexibility and efficiency of the production line.

Ensure product quality

(1) Uniform mixing ensures quality: The weight mixer adopts an efficient mixing mechanism, such as a rotating cylinder and a high-speed mixer, to ensure that all components are evenly dispersed, avoiding material layering or agglomeration, which is important for the stability of plastic product performance.

(2) Real time monitoring and adjustment: Equipment is usually equipped with sensors and control systems, which can monitor key parameters during the mixing process in real time, such as temperature, pressure, and uniformity of the mixture, to ensure that the production process meets preset quality requirements.

Reduce production costs

(1) Reduce material waste: By precise weighing and mixing, the use of expensive raw materials can be reduced without affecting product quality, effectively reducing costs and material waste.

(2) Improving equipment utilization efficiency: The high efficiency and reliability of equipment reduce maintenance and operation costs. At the same time, due to its high output and low failure rate, the utilization efficiency of equipment is greatly improved, saving more costs for enterprises.

Adapt to diverse production needs

(1) Multi purpose adaptability: The weight mixer can handle a variety of different plastic raw materials, including powders, particles, and liquid additives, which enables it to adapt to various production needs, including the manufacturing of different types of plastic products.

(2) Customized production: The flexibility of the equipment enables it to quickly adjust to adapt to new formulas or changing production needs, providing greater production flexibility and the ability to respond quickly to market changes.

In summary, the widespread application of weight mixers in the plastic manufacturing industry not only improves production efficiency and product quality, but also brings significant economic benefits to enterprises. Weighing mixer provides strong support for the development of the plastic industry and helps enterprises maintain a leading position in fierce market competition.