Product introduction

The 300G vacuum suction machine is an efficient and energy-saving raw material conveying equipment that uses advanced vacuum adsorption technology to quickly and stably transport various powdered and granular materials. Widely used in industrial production, especially in applications such as injection molding and extrusion that require a large supply of raw materials. This device uses the principle of vacuum adsorption to move materials from one place to another, which not only improves production efficiency but also ensures the continuity and automation level of the production process. This model supports customization and can adjust parameters such as conveying volume, conveying height, and distance according to customer needs to meet the needs of different production scenarios.

Technical parameters

| Model | Motor | Transmission capacity ㎏/hr | Filter | Static pressure | Airflow | Pipeline diameter | Door of the reserves | External dimensions | |||

| Type | Format | 5M | 10M | 15M | main body (HxWxD) | ||||||

| RL-300G | Carbon brush type | 1.1KW | 300 | 200 | 140 | nothing | 1300 | 2.7 | 38㎜ | 7.5L | 34x34x59㎝ |

* The parameters are for reference only and support customization.

Application function

- Automated conveying: Achieve automated and continuous conveying of raw materials to improve production efficiency.

- Energy saving and environmental protection: Adopting the principle of vacuum adsorption, reducing the friction between materials and conveying pipelines, and lowering energy consumption.

- Reduce manual operations: Reduce the labor intensity of manual feeding and lower labor costs.

- Modular design: facilitates maintenance and replacement, and improves the maintainability of the equipment.

Product features

- Customized services: Provide personalized customized solutions based on the specific needs of customers.

- Efficient conveying: Adopting vacuum adsorption technology to ensure fast and stable material conveying, the suction time can be freely set, and automatic buzzing alarm notification for material shortage.

- Easy to operate: microcomputer control, user-friendly design, making operation simple. Stainless steel storage bucket, lightweight, durable, easy to clean, easy to maintain, precise control of operation.

- Safety and reliability: Multiple safety protection measures, motor overload automatic protection device, and shortage alarm indication ensure the stability and safety of the equipment during operation.

- Widely applicable: Suitable for conveying various powdered and granular materials, such as plastic pellets, chemical raw materials, etc.

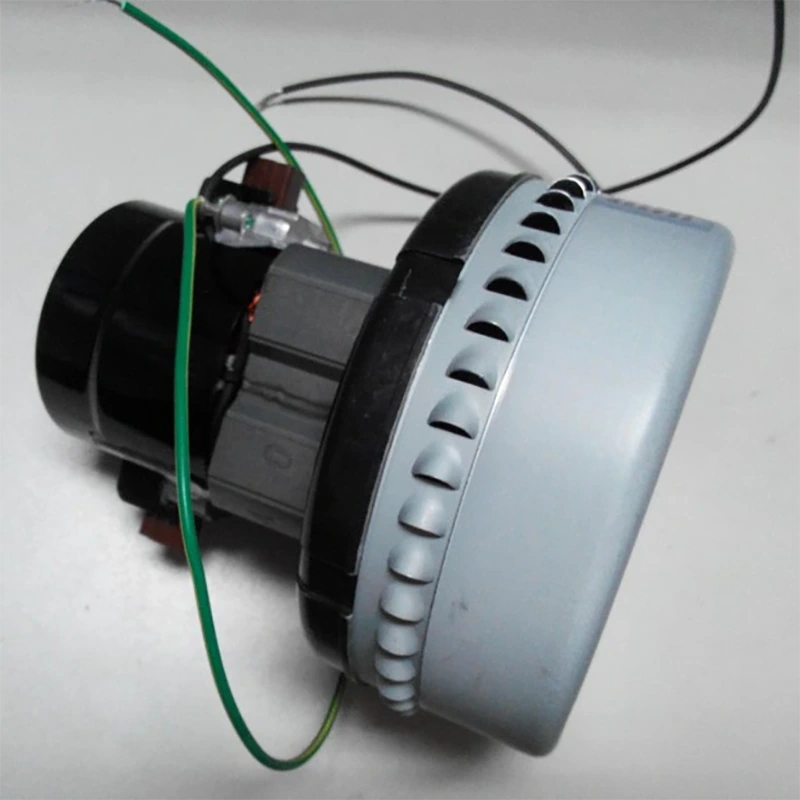

- Complete configuration: independent filter device for easy removal of dust accumulation; Silent device to reduce operating noise; Motor Amedege, Schneider Electric, Kanglong microcomputer controller.

Installation of 300G vacuum suction machine

The 300G vacuum suction machine supports customization, bringing convenience and efficiency to your production while also meeting your special production needs. We can provide you with satisfactory solutions in terms of conveying capacity, conveying height, and other technical parameters.

Reviews

There are no reviews yet.